News

Custom Color Matching to Create Customized Solutions

How Star Plastics’ Specialty Opens New Possibilities

From consumers to OEMs, it’s no secret that we all love customization. From choosing the exact color of our shoes to making a phone case that is uniquely ours, it is not hard to understand why we all love personalizing things – it shows our personality.

At Star Plastics, custom color matching is a particular specialty. Our history and experience in this area allow us to deliver the best custom color solutions. With our experience – and over 2,000 Pantone colors – the possibilities are nearly endless for custom color compounding. However, precisely matching color is more complicated than it seems.

What is Custom Color Compounding?

Custom color compounding is the process of matching your exact color from a part, pellet, RAL color, color number, Pantone or chip to create a pre-colored, custom plastic material to meet your specification needs.

As a custom compounder, Star Plastics specializes in delivering unique products based on customers’ color requirements that also meet performance, property and price requirements.

The Color Matching Process

At the start of any custom color matching process, the Star Team requires two things: the color to match and the desired base polymer. Star Plastics can color match nearly any polymer in base or glass including, ABS, PC, PC/ABS, PC/PBT, PC/PET, Nylon 6 and 6/6 plus propylene. Plus, glass-filled PET and glass-filled PBT, PP.

The ideal sample for matching is a standard plastic chip in the chosen polymer. However, our technical team can successfully create custom color matches from parts, pellets, metal plaques, RAL standard colors, color numbers, Pantones and even leather swatches.

Once our lab team understands the melt flow and the number of chips or pounds from the customer-selected polymer, we supply the target with its own L*a*b* color value.

Utilizing our X-Rite Color iMatch software, the most advanced technology in the industry, our team can see which pigments to use to begin the matching process, which allows us to obtain accurate color matches fast.

From there, our team uses the system to match the color, where it is then formulated, extruded and molded for evaluation before being sent to the customer for approval – usually within seven days.

Overall, once the target is in-house, the entire custom color match process can take less than two weeks – compared to compound competitors and major manufactures who deliver anywhere from four to twelve weeks.

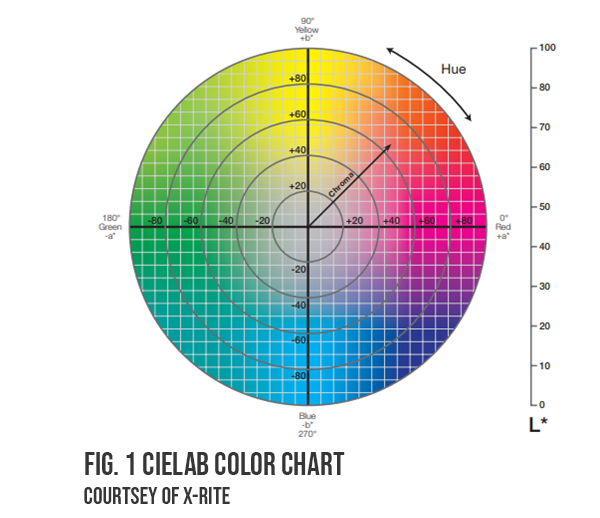

At Star, the testing and quality standards built into our custom plastic compounding process are why we are known for our lot-to-lot consistency. We apply these strict standardsto every single run to create consistent results – meaning the formulation color is just another measurement. Using Figure 1, an example of this would be if we run a Gray GUIS 3000-35, we can retrieve the run data and final color numbers from recent production to ensure that we don’t jump the axis but land in the same consistent range.

With many of our custom color pellets used in two-piece parts, lot-to-lot consistency is crucial to allow no visible differences if they have to snap them together. At Star Plastics, our team is able to move less than .3 staying within the axis for L, A and B – proving incredible accuracy.

The Benefits of Custom Color Matching

While plastic processors have options to produce their color-specific parts, from adding concentrate to the natural material at the press to seeking color masterbatch services from an outside vendor, the best option may be using pre-colored material.

Many injection molding machines have screws designed to feed and move material into the tool – these screws, however, were not created to mix material. When processors add color to natural materials at the molding machine, many will experience swirl marks, surface issues and color variants far from specifications.

Specializing in high-quality custom color compounding, we have equipment specifically designed for custom color work.

Other benefits include:

- Faster lead time

- Lot-to-lot consistency

- Single supplier source, providing one point of contact for any issues

- Single SKU to manage instead of two, which also keeps inventories lower

- Eliminates the need for secondary services such as painting or labeling to reduce cost

How the Demand for Custom Color Compounding Has Grown

No matter the product, nearly everyone has a color preference in mind. Long gone are the days of standards such as 2501, 2302 – all these have gone by the wayside. At Star Plastics, we continue to see an increase in demand for custom color matching after customers consistently see our ability to match a color successfully. The explanation for this demand is simple – custom color matching allows for new branding opportunities.

Working with OEMs, Star Plastics has helped many create new electrical boxes in safety colors – bright red, yellows, greens. While these bright colors are often the most challenging to match, our 30+ years of experience and technical support team are essential to producing a new product with the highest quality and most accurate color matches.

The Star Advantage

Star Plastics is not the only custom compounder that can provide color matching. However, not many providers can match the accuracy, expertise, quality and speed that we provide. Custom color compounding is a specialty of ours because it’s the majority of what we do – 85% of our total pounds of polymers sold are custom color processed.

With custom color available in all of our product lines, including StarPrime®, ValuPak® and ReStart®, Star Plastics can match any hue, allowing our customers to expand their inventory with new levels of quality and color. Beyond the ability to take natural polymers and color process them to your needs, Star Plastics can also custom color pre-colored polymers or recycled content.

Using a customized color matching process unique to Star Plastics, all of our orders are tracked in our internal color system. We can then base all future orders on historical data with the initial standard color, protecting against color shift over time. This system supplies custom color compounds with the best lot-to-lot consistency in the industry regardless of how far apart orders are places.

When you need a custom color compounder, trust Star Plastics to deliver the most accurate custom color matching, quick turnarounds and the high quality you expect.

Ready to see how Star Plastics can help you create the perfect custom color molded part? Click here to contact us.