News

Plastics Compounding 101: The Art & Science of Custom Plastic Compounding

Manufacturing and delivering plastic compound solutions is just as much of an art as it is a science. While technical, scientific knowledge of material is required to tailor custom formulated compounds to exact specifications and performance characteristics, there is an art to the intentional material customization and design that comes with years of real-world formulation experience.

What is Plastic Compounding?

Plastics compounding is the process of taking basic, raw plastic material and customizing it with various additives to achieve color, property and performance requirements. Lab formulation and physical processes achieve this by combing the necessary additives and color to the plastic resin.

At Star, we manufacture polymer compounding solutions for our customer’s final products to perform in its application as good as, if not better than, any other material in the marketplace. When you count on us to provide solutions, you can trust that the plastic compound will perform. We understand that each application has different requirements, and Star Plastic compounded materials will meet those requirements every time.

The Plastic Compounding Process

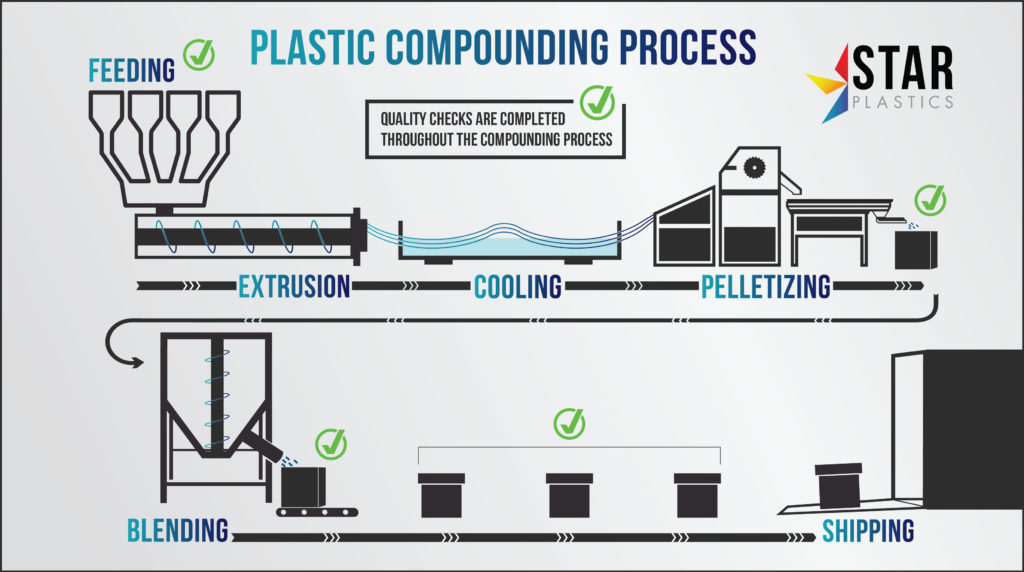

While most would consider that the plastic compounding process begins with a polymer or base resin, at Star, we believe that feedstock testing is first and foremost to kick off our successful process. Our process includes:

- Feedstock testing

- Masterbatch creation and prework testing

- Compounding and in-process testing

- Post-blending and final quality control testing

To meet our two-week lead time, our top-to-bottom process and review moves quickly. Feedstock sampling, purchase and qualification support this quick turnaround, as our labs pre-qualify all base raw materials for performance characteristics before an order is even placed by a customer.

Once an order for a Star plastic compound comes in, the process begins with selecting the pre-certified base feedstock that suits the application. From there, our team works to complete the prework and formulation needed to create the masterbatch. We also complete pre-testing in this phase, which is the first of many checks on color and material properties to ensure it is within the customer’s specification.

After the prework stage, we shift to “line time” for the compounding run. Feeders draw in raw material, where it is mixed in with additives, using computerized control of portions to ensure proper ratios. The horizontal screws of the feeder slowly move the material forward while homogenizing the material before it gets to the extruder.

Once it is in the extruder, the material is heated and becomes molten plastic, while continuously being blended by the extruder screws. After it is completely homogenized, the molten plastic pushes through the die-head to form plastic strands, which then pass through a water bath to cool. During this time, we monitor the temperature of the water to ensure proper cooling before the strands are pelletized, as the temperature affects the size of the pellets produced.

Following the cooling, the material enters the pelletizer. The helical blades of the pelletizer have multiple knives that operate at a certain speed to create exact and consistent sized pellets. The newly formed pellets fall onto a screener, assuring only consistently sized pellets move to the finished goods gaylord box.

Finally, the finished goods boxes are tested before being taken to the post-production blender, which homogenizes the material once again to create lot-to-lot consistency.

Testing – Our Competitive Advantage

Nearly every vendor that comes through our lab believes the same thing; we test too much. The amount of testing is done for good reason—when we sell a material, it stays sold. We ensure that quality is met with our thorough in-process testing.

Star Plastics has in-process testing for each box to ensure that the customer requirements are being met at every step. As mentioned, we begin our process with testing of the feedstock before and after the material is purchased, prior to use in formulation. Feedstock testing ensures that we know the properties of our base materials, which will affect the prework and formulation that happens once an order is placed.

Once prework begins, our lab team formulates and tests the material on a small scale until we achieve the right properties and color. They create the masterbatch based on these ratios for the processing run. Our lab is critical to our ability to produce polymer compounding solutions.

Using salt-and-pepper blends during prework, the lab team creates the masterbatch and returns to the lab for testing to ensure that the masterbatch and feedstock behaves like the salt-and-pepper blend. We complete this prework in order to eliminate adjustments to the material while it is on the line.

When creating the masterbatch, our goal is to create a material for compounding that requires minimal changes in all physical properties, color and flame retardancy. If we are running a 40,000-pound truckload order of a finished product on the line, we are under two changes on average. Throughout the entire run, Star team members monitor these properties.

For example, as the compounding process progresses, a team member tests the material comes out of the pelletizer. By testing every step of the way, we can adjust the plastic compound formula, specifically the properties, color or size, if anything is off-target. These changes could include adjusting the speed of the screws, temperature of the extruder, or correcting the base resin ratio and the additives used.

When the material reaches the post-compounding stage of our process, it is subjected to one last inspection. The final lot certification serves as a concluding review. While we rarely find issues in this stage, as any abnormalities are caught and corrected earlier in the process, this conclusive test serves as a final safety net.

At Star, even with our tight two-week lead time in mind, we never sacrifice the quality of the product. Our team will not ship the finished goods material until our lab submits a quality-control results sheet or customer-supplied quality control form that shows that the material complies with the product release.

Quality – Star Plastic’s Key to Success

At Star, incremental quality checks and testing is built into our internal process because ensuring quality is the most important aspect of serving our customers. We have built a reputation for quality products that gives our customers peace of mind; they know that when they order from us, we will provide trusted quality products every time.

With more than 30 years in business as a custom compounder and processor, as well as employees with over 20 years of direct lab experience at Star, we have the material formulation, product knowledge and custom color matching expertise to support our reputation of quality.

Our success, however, comes as a result of our ability to always look to improve, and our quality testing is how we achieve it. Each week, leaders from our manufacturing team and lab meet to analyze the runs of the past week. In these discussions, we aim to highlight what went well and what we can do better.

By the end of these meetings, our goal is to identify any potential problems and work towards solutions for them. With this culture of continuous improvement opportunity, we can increase the quality and productivity of our team and products while reducing downtime. We have achieved a material satisfaction rate of 98.6% over the past three years because of this.

Custom Polymer Compounding with Star Plastics – Quick Facts

Serving as your custom plastic compound specialists, our team is here to help answer some of the common questions that we get about the polymer compounding solutions we provide.

How long will my material take to ship?

Our lead time is two weeks on standard production orders, up to 50,000 pounds. At Star, we work hard so your material is on time, every time. In 2020, our on-time delivery rate is 99.8%!

Can you pre-color my material to a custom color?

Yes, we specialize in creating unique products based on customers’ color requirements. Star has the capabilities to match your exact color and create pre-colored custom plastic materials to meet your specific application needs. More than 85% of the total pounds of polymers sold by Star Plastics are custom color and recurring orders.

Are my polymer compounds made from regrind?

No, compounded products does not mean it is inherently regrind-based or recycled. However, we do have a specific product line called EcoPlas® that intentionally uses secondary feedstocks to target lower end applications with broader property requirements and lower price points.

What is repro made from?

Repro, or recycled plastic raw material, is simply combining regrind and secondary feedstock streams, and the result can be a mystery. Without prework, post-production blending, continual specification checks or material stability checks, you are taking a gamble that the material you receive will fit your needs.

Star Plastics custom manufactures material, meaning that all of our plastic compounded products are made to our customer’s specifications and regularly tested. Our knowledgeable staff works closely with you to design the ideal material for your application.

What quantities of material do you offer?

As a full-service plastics company known for custom color accuracy, we have the ability to produce batches of any size. From a small lot to railcar size quantities, no job is too big or too small!

Specializing in custom formulated engineering grade resins, Star Plastics is a leading producer of high-quality grade custom compounds. No matter what your plastic compounding needs are, Star can manufacture and provide custom polymer solutions meeting your specific requirements in performance, property and price. Have a specific color need? Star Plastics also specializes in custom color solutions.

Want to learn more about how Star Plastics can help your custom plastic compounding needs? Contact us today!